[Chapter 1] Section 2 Scaffolding Material, Structure, and Assembly Drawing⑦

8 Precautions for assembling, dismantling, etc., of scaffold

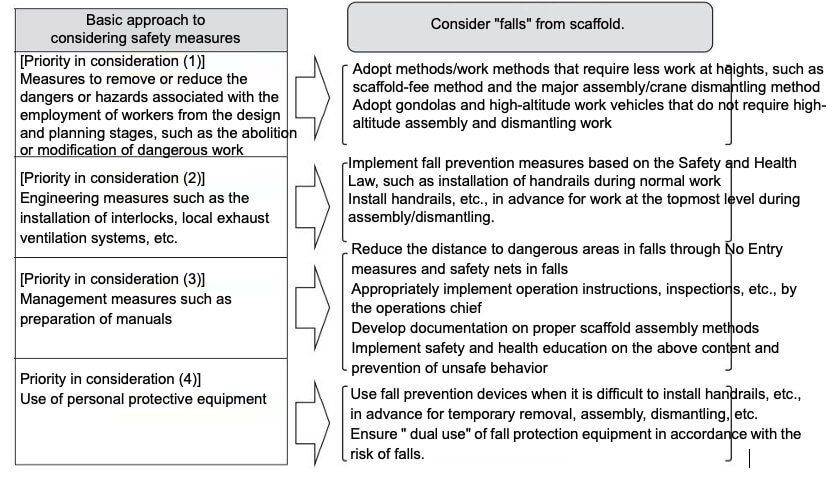

(1) Concept of risk assessment at the time of work planning

1.When planning work, consider essential fall prevention measures based on the anticipated work procedures, change materials, etc., and select various safe construction methods.

2.Consider procedures to prevent falls without the use of fall protection equipment as much as possible.

3.Incorporate the results of the risk assessment into work procedures.

4.The operations chief, etc. make the completed work procedures known to juniors and share them.

5.Use fall prevention equipment as a “precaution” or “last resort.

6.Do not have the mindset of “just use fall prevention equipment” if something happens.

7.Use fall prevention equipment in useful situations.

8.If the use of fall prevention equipment is not effective, devise ways to use them or install fall prevention equipment such as netting.

9 Scaffolding assembly work instructions

(1) Work procedures basically use verbs to describe body movements.

For example, “do ____,” “install ____,” and “remove ____.”

As a general rule, work procedures are prepared by the primary subcontractor on the company’s responsibility. The work procedures are then checked by the primary contractor and distributed to the subcontractors if approved. Secondary or tertiary subcontractors, etc., use the work procedures prepared by the primary subcontractor as the basis for their own work.

Example of assembly workflow of prefabricated scaffold level 1

| Procedure | Addendum to the main points (Safety, success, and ease of doing) |

|---|---|

| 1. Clear the ground | ・Scaffold footings to be level. ・(If there is a risk of subsidence) perform after rolling pressure |

| 2. Line up the planks | ・The width should be about 200 mm between the outer wall of the building frame and the inner width of the sill plate. ・Match the width of the building frame |

| 3. Place the jack base | ・At 1,800 mm intervals ・After adjusting the initial height to ◯ ◯ cm |

| 4.Erect the frame | ・Insert it into the jack base. |

| 5.Install the diagonal brace | ・One person holds the frame ・To the left and right |

| 6.Erect the frame | |

| 7.Install the diagonal brace | ・Connect the frames of 4. and 6. |

| 8. Repeat 6. – 7. until 6. | |

| 9.Repair the passage of frame |

・Parallel to the outer wall of the building frame ・So that the jack base is in the center of the planks. |

| 10.Adjust the height of the frame | ・Use the level, turn the jack handle, |

| 11.Mount the bridge batten pipe | ・Girder direction first ・The distance between the outside wall and the frame is ◯ ◯ cm. |

| 12.Nail the jack base | ・Two places with one |

| 13.Attach the handrail frame | ・Check the fixing method. |

| 14.Attach floor ledger form | ・Don’t let fingers get caught in hook. |

* The steps may switch in some cases.

Names of parts used for assembling work, etc., of scaffold

| Assembly etc., of scaffold |

General term for scaffolding assembly, alteration, and dismantling operations |

| Building frame | Structural member made of steel pipe welded into a torii-shape |

| Diagonal brace | X-shaped reinforcement to prevent buckling under load |

| Floor ledger form (Anti) | Ledger frame with a work floor |

| Ledger form | Frame-Like member connected in horizontal direction |

| Lower rail | Horizontal member for fall prevention for frame assembling scaffold |

| XX rail | Horizontal member for fall prevention (handrail at top) |

| Handrail frame | Member for fall prevention integrating handrail and diagonal brace |

| Standards | Main vertical member of scaffold |

| Work floor | Space for work |

| Single-pipe scaffold | Scaffold installed by combining steel pipe and fastening metal fitting |

| Single-pipe | JIS standard steel pipe |

| Tensioning metal fitting (Clamp) | Hardware for connecting steel pipes, fixed at 90 degrees and free at 360 degrees |

| Single-pipe joint | Hardware that connects steel pipes |

| Handrail | Horizontal member for fall prevention to be mounted on upper stage |

| Middle rail | Horizontal member for fall prevention to be attached to second stage |

| Baseboard (150 mm) | Horizontal member for fall prevention provided on working floor |

| Baseboard (100 mm) | Horizontal member for preventing falling object installed on working floor |

| Bridge batten | Ledger material in the direction of girder (longitudinal direction) for fix the height of scaffold horizontally |

| Ledger pipe | When it is attached to the foot of the ledger material (pipe) in the direction of girder (length) connecting horizontal direction, it is called “root girdle pipe.” |

| Beam direction | Between the front and back steps |

| Brace | Reinforcing material for preventing buckling |

| Large brace | Buckling prevention reinforcing material provided on the entire structure surface |

| Firing pipe | Member for reinforcing corner part for preventing distortion |

| Binding part | Connection for fixing wedge binding scaffold |

| Safety net | Net for fall prevention (Anti-Net) |

| Vertical net | Fall prevention net (Mesh sheet, etc.) |

地域・講習・人数に合わせてすぐに予約可能

講習会を予約する受講者様のご希望に合わせ、以下のタイプの講習会もご用意しています

このページをシェアする

講習会をお探しですか?