[Chapter 2] Section 2 Power equipment

1 Electric hoist

(1) Electric hoists can safely and efficiently lift and lower scaffolding materials and other objects by hanging them on special brackets. Although no formal training is required, it is desirable to appoint workers who have completed special crane training or who are certified in slinging, since the work of applying wire ropes to loads is the same as that of slinging.

1. Inspect before starting work.

2. Be especially careful not to allow the wire rope to wind up unevenly.

3. To prevent random winding, connect the rope to the hook and apply a little tension from below when idle-hoisting.

4. The above measures are also useful in preventing shaking during hoisting

(Photo: Toyo Koken Co., Ltd. product)

2 Winches for unloading scaffolding

(1)In recent years, equipment manufacturers have developed winches for unloading scaffold lumber.

Those who have completed special training in winch are appointed to operate the winch.

1. Two-speed operation (low-speed and high-speed)

2. Slow start/stop and less load shaking

3.Emergency stop button

4. Voltage, current, operation time, etc. are monitored to prevent breakdowns.

3 Lifting bags and ropes

(1) Lifting bags are exclusively designed and must be selected and used in consideration of the load to be carried. As the base can become heavily damaged, they must be thoroughly inspected before starting the work.

In some cases, the base comes off, causing the contained materials to spill out during work.

(2) For the lifting rope, it is safer to use an attendant rope for slinging operations. Those hanging loads will find it easier to use if it is equipped with a dedicated suspension hook.

(1) When using a suspension rope, use a special bracket or pulley.

(2) When raising and lowering scaffolding materials by hand, workers should be positioned at an angle to avoid working up and down.

(3) When lifting and lowering scaffolding materials, a supervisor should be assigned and the areas where materials may drop should be off-limits to all persons except those involved.

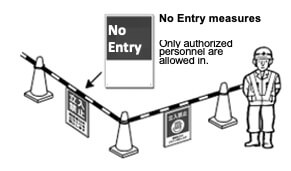

4 No Entry measures

(1) When there is a risk of danger to workers due to objects falling during work, measures shall be taken to prevent such danger, such as installing anti-netting equipment and setting up an entry zone.

1. Completely enclose the restricted area with solid fences, barricades, etc.

2. Put up a no-trespassing sign so that everyone can see it

3. Assign observers as needed.

5 Knowledge of cranes, etc.

(1) When work is to be performed at a height of two meters or more, workers must not be allowed to work if there is a risk of danger due to strong winds, heavy rain, heavy snow, or other adverse weather conditions.

1.Strong wind: Wind with a 10-minute average wind speed of 10 meters per second or more

2.Heavy rain: Rainfall with a single rainfall of 50 mm or more (regardless of time)

3.Heavy snow: Snowfall of 25 cm or more at a time (regardless of time)

4.Earthquakes of moderate intensity or greater: Earthquakes with a seismic intensity of 4 or greater

(2)workers must not be allowed to work in bad weather

1.Steel frame assembly work, etc.

2.Assembly, etc., of wooden buildings

3.Assembly of work platform

4.Mobile crane operation

5.Work at heights of 2 m or more

6.Dismantling work of concrete structures

7.Assembly etc., of scaffold

8.Crane operation

9.Gondola work

(3)Measures to be taken when bad weather is expected

1.Winding or removing mesh sheet

2.Reinforcing wall ties, stay pipes, etc.

3.Lashing work floor, etc., at the top

4.Horizontal connection and reinforcement using ledgers to prevent land subsidence in scaffold

(4) When working at high places of two meters or more, maintain the lighting necessary to safely perform the work. Although laws and regulations only state “necessary lighting intensity” for work performed at high places, ensure sufficient lighting by installing floodlights or fluorescent lamps before it gets dark.

□ Lighting (lux) is required by law as follows.

1.Precision work 300 lux or more

2.Normal task 150 lux or more

3.Rough work 75 lux or more

地域・講習・人数に合わせてすぐに予約可能

講習会を予約する受講者様のご希望に合わせ、以下のタイプの講習会もご用意しています

このページをシェアする

講習会をお探しですか?