[Chapter 3] Section 2 Methods of Use and Maintenance/Inspection of Protective Equipment

1 Fall prevention equipment

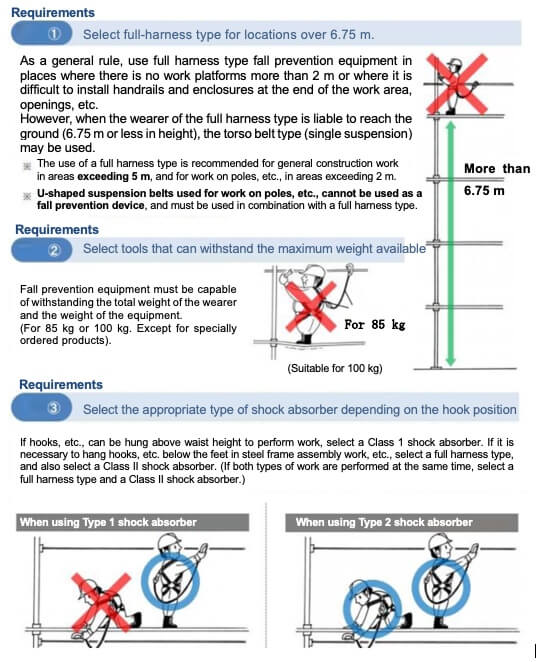

(1) In principle, full harness-type fall prevention equipment should be used. However, if the wearer of full harness-type equipment is likely to reach the ground in a fall (height of 6.75 m or less), a “body belt-type” (single suspension)” can be used.

(2)How to use

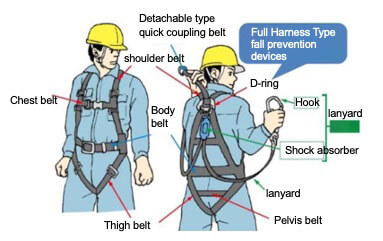

1.Check the instruction manual to make sure that all parts necessary for safety are present, and attach the lanyard securely with no loose parts.

2.The attachment equipment of the fall prevention equipment must be such that there is no risk of the lanyard coming off or disconnecting, and must be able to withstand the impact force at the time of fall prevention.

3.To prevent the lanyard from falling off or being damaged due to bending force applied to the hooks after falling, install the lanyard so that the main axis of the hooks and the direction of the force applied at the time of the fall are aligned.

4.When attaching the hooks of a fall arrest device to a vertical main rope, attach the attachment facility, such as a lollipop fitted to the main rope, to the connector of the detachable belt. The position of the attachment facility must be no lower than the position of the ring that joins the lanyard to the full harness, etc.

5.Make sure that the horizontal main rope is stretched higher than the ring that connects the lanyard to the full harness, etc., and attach the hook of the fall prevention equipment to the lanyard.

6.Always use two lanyards.

(3)Inspection, maintenance, storage, and disposal standards

1.The inspection, maintenance, and safekeeping of fall prevention equipment must be performed by designating a person in charge, etc., and the results of such inspection, maintenance, and safekeeping must be recorded in a control ledger, etc., as well as other items necessary for management.

2.Do not use any device that has been subjected to the impact of a fall, even once. Also, items that have been found to have abnormalities as a result of inspection, or items that have deteriorated severely due to wear, scratches, etc., must not be used..

Workers who perform the following types of work must receive special training

Work involving the use of full harnesses of fall prevention equipment at a height of 2 meters or more where it is difficult to provide a working floor (excluding work involving work at high places with ropes).

2 Protective helmets, etc.

Wear a safety helmet in places with danger of scattering/falling objects, danger of falls, and danger of electric shock. Workers are obligated to follow the instructions given by the employer.

(1) Standards for Protective Helmets (Ministry of Labor Notification No. 66) Meaning of Terms

(i) Helmet body is the part that covers the head of a person wearing a helmet.

(ii) Body is the part consisting of a hammock, headband, ring strap, etc., which is attached to the inside of a helmet to cushion the impact on the wearer’s head when the helmet is subjected to an impact.

(iii) Shock absorbing liner is the part attached to the inside of the cap body to reduce the impact applied to the head of the wearer when the helmet body is impacted.

(iv) Chin strap is the part for preventing the helmet body from falling off the wearer’s head.

(2)Safety helmets must satisfy to the following:

(i) Does not corrode easily.

(ii) Does not damage the skin.

(iii) Has heat resistance, cold resistance and water resistance suitable for the purpose of use.

(3)Safety helmets must have the following markings in a readily visible place:.

(i) Manufacturer’s name

(ii) Date of manufacture

(iii) That they are designed to prevent danger resulting from scattering or falling objects or due to falls

Although it varies depending on the material and usage conditions, the Japan Helmet Manufacturers Association requires that protective helmets made of thermoplastic resin such as PC, ABS, and PE be replaced within three years of use even if no abnormalities are found in their appearance, and protective helmets made of thermosetting resin such as FRP be replaced within five years of use even if no abnormalities are found in their appearance.

地域・講習・人数に合わせてすぐに予約可能

講習会を予約する受講者様のご希望に合わせ、以下のタイプの講習会もご用意しています

このページをシェアする

講習会をお探しですか?