[Chapter 3] Section 2

1. Based on the results of accident analysis

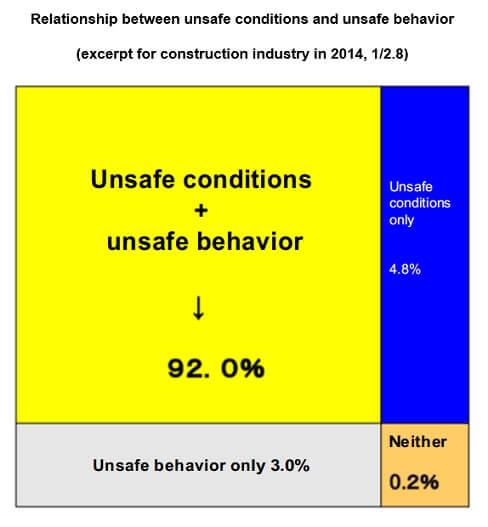

Generally speaking, analysis has shown the direct causes of most industrial accidents to be unsafe behavior and unsafe conditions.

Even if a person working in an office on the 10th floor of a building walks around the room a little absentmindedly, he or she will never fall to the stories below because there is a floor.

In this case, there is no unsafe condition with respect to falling, so even if a person tries to fall, they won’t. Now, what if the same 10th floor is under construction?

To avoid a condition with no safety rope, work on the steel framework is likely to be carried out using, for example, the double lanyard method. An unsafe condition is recognized here, i.e., a clear danger of falling, so the rule of using a double lanyard is established as a safety measure. (Of course, there is also likely to be a safety net.)

To avoid a condition with no safety rope, work on the steel framework is likely to be carried out using, for example, the double lanyard method.

An unsafe condition is recognized here, i.e., a clear danger of falling, so the rule of using a double lanyard is established as a safety measure.

(Of course, there is also likely to be a safety net.)

In this case, examples of unsafe behavior would be working on the steel frame without fall arrest equipment (a safety belt) or a helmet, or moving while in a state with no safety rope, where the hook has not been attached to anything.

It should be easy to understand that an accident may easily result if unsafe conditions and unsafe behavior are present at the same time.

Also, it should be possible to reduce accidents if either one can be mitigated.

Safety realization ➡ Concrete, specific reductions in “unsafe conditions”

and “unsafe behavior” at the worksite

2. Industrial accidents arise due to mistakes in human judgment

From the perspective of accident analysis, the key factors are definitely “unsafe conditions” and “unsafe behavior.” However, as shown in the previous example, it is not easy in practice to reduce “unsafe conditions” especially in the construction industry.

Safety is also affected by the fact that work cannot be done without unavoidably confronting danger due to progress of the work process, as well as external factors like seasons and the weather.

This section will focus on the other factor, human behavior.

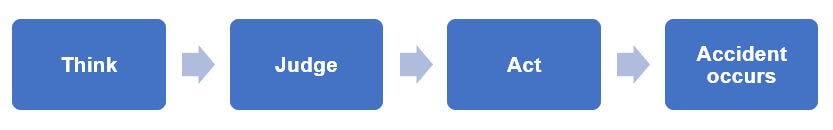

- ■ If you are thinking about moving and take a shortcut (behavior) because “there’s nothing to worry about” (judgment), the probability that an industrial accident will occur increases.

-

■ “Unsafe behavior” is generally said to be one of the causes of industrial accidents, but in reality, there is always a mindset of allowing violation of laws and rules before an accident occurs. (Bad judgment)

Failure to comply with laws and regulations,

disobeying office rules,

selfish interpretation…

Industrial accidents will always occur as long as we are willing to forgive these things. - ■ Also, human lapses with no ill-intent, like carelessness, absentmindedness, and misunderstanding, are also factors in the occurrence of industrial accidents, but they are not thought to account for much of the total.

- ■ Problems with machinery, equipment, and other things (unsafe conditions) are also a factor in the occurrence of industrial accidents, and yet another factor is failure to properly carry out inspection before starting work because it’s troublesome or “we’ll be okay without it.” Inspection during patrol is meaningless if it’s not done properly. In the end, a high percentage of unsafe conditions are caused by humans.

- ■ Poor management can lead to unsafe behavior and unsafe conditions. However, management too is a matter of thinking, judging, and acting by human beings, and thus it can be concluded that “industrial accidents will occur if people do not make the right decisions and take the right actions.”

[That’s too much trouble.

There’s nothing worry about, it’ll be okay.]

If we can get rid of this thinking, we can prevent many labor accidents!

受講者様のご希望に合わせ、以下のタイプの講習会もご用意しています

このページをシェアする

講習会をお探しですか?