[Chapter 3] Section 8 ③

3. Accident examples and countermeasures②

- [Example 4]

Worker stepped off his foothold and fell while painting a steel frame -

[Accident situation]

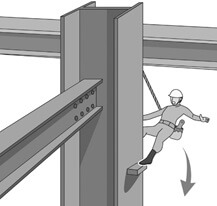

In this accident, a worker using a step on a steel column as a foothold was engaged in painting a steel frame at a construction site for a new 7-story building. He stepped off the foothold and fell.

On the day of the accident, Worker A was engaged in painting touch-up work on columns, beams, etc., where paint had peeled off during the assembly of the steel frame, near the fourth floor of the building. He was working with his foot on a step mounted to the column, but the step did not have sufficient area, so he accidentally stepped off and fell about 7 m onto the concrete floor of the third floor, and was seriously injured.

A was wearing a safety belt and a safety helmet during painting work. He was using the fall arrest equipment by attaching its hook to a protrusion on column (a piece hanging on the steel column). However, the rope was cut at a point about 20 cm away from the hook due to the impact of A’s stepping off.

A’s fall arrest equipment was for single suspension, and since it had been 6 years since it was manufactured, the rope was discolored, and there were burn marks and paint deposition everywhere. The rope consisted of eight strands, some of which had been broken for some time. At this construction site, no standards had been prepared for inspection of protective equipment such as fall arrest equipment, and inspection of protective equipment was left to the worker.

At this construction site, the painting touch-up work for the steel frame was scheduled to be completed in one day, so no working floor was installed, and no fall prevention measures were taken, such as setting a protective net.

[Cause]

1) The work was carried out using a step with insufficient area as a foothold.

2) There was no protective net, even though there was no working floor.

3) No standards had been prepared for inspection of protective equipment such as fall arrest equipment, and inspection of protective equipment was left to the worker.

[Countermeasures]

1) When carrying out work at a high place, provide a working floor by assembling scaffolding, etc.

2) If work at a high place using fall arrest equipment is unavoidable, there are limitations on the use of fall arrest equipment, such as when moving the work location, so also set a protective net, etc.

3) Prepare standards for inspection of protective equipment such as fall arrest equipment, and check the inspection results.

Workers must never be made to use fall arrest equipment if it has deteriorated over time, or declined in strength due to contact with a sharp-cornered steel frame, damage due to welding flame, etc.

- [Example 5]

Worker made a misstep and fell during steel frame assembly work -

[Accident situation]

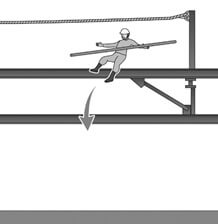

This accident involved the fall of a worker carrying lip channel steel material (C-shaped steel) (cross sectional shape: 100 x 50 x 20 mm; length: approx. 4 m; weight: approx. 16 kg) on a beam at a height of about 8 m in steel frame assembly work for construction of a new 2-story store.

On the day of the accident, several groups of workers entered the construction site, and 6 workers including A were instructed by site manager B to install C-shaped steel and braces.

A was in charge of carrying the C-shaped steel, unloaded onto the beam with a mobile crane, to the installation position. However, about two hours after starting work, A was carrying the C-shaped steel with both hands while walking on a beam 10 cm in width, and he misstepped and fell. A was immediately rushed to the hospital, but died.

On the day of the accident, another group of workers was instructed by B to set a horizontal safety net in parallel with installation of the C-shaped steel and braces, but when A fell, the net was not in place yet. On the beam where A misstepped, a main rope for fall arrest equipment was installed. A was wearing fall arrest equipment, but did not attach the hook to the main rope. At the site, B had been appointed as operations chief for assembly, etc., of the steel frame of buildings, etc., but he did not confirm whether A and others were using fall arrest equipment because he was carrying out several types of work simultaneously.

In addition, A came onto the site for the first time on the day of the accident, and he was assigned to work without receiving any safety and health education at the time of entry.

[Cause]

The following are possible causes of this accident.

1) The victim was not made to use fall arrest equipment.

2) The work plan was inappropriate, e.g., it called for carrying work on the beam while the horizontal safety net was still not set.

3) B, who was appointed as an operations chief for assembly, etc., of the steel frame of buildings, etc., did not perform his duties as an operations chief, such as monitoring the use of fall arrest equipment and direct supervision of work.

4) A was assigned to work without receiving any safety and health education on work methods and work procedures, which is supposed to be provided to those who enter a work site for the first time.

[Countermeasures]

1) Ensure consistent use of fall arrest equipment in steel frame assembly work.

2) Formulate work plans in which measures to prevent danger, such as workers falling, are implemented first.

Formulate a work plan which starts work at high places after measures have been taken to prevent workers from falling.3) Have the operations chief of assembly, etc., of steel frame of buildings, etc., reliably carry out the following duties:

[1] Deciding on the method of work and assignment of workers, and directly supervising the work.

[2] Inspecting the functions of equipment, tools, fall arrest equipment, etc., and safety helmets, and eliminating any defective equipment.

[3] Monitoring the use of fall arrest equipment, etc. and safety helmets.4) Provide safety and health education that should be given to all new workers entering the site, and assign them to work after education about the danger of falling and work methods, etc.

受講者様のご希望に合わせ、以下のタイプの講習会もご用意しています

このページをシェアする

講習会をお探しですか?