Guidelines on the Safe Use of Fall Arrest Equipment①

Guidelines on the Safe Use of Fall Arrest Equipment

(Labour Standards Bureau Notification No. 0622-2 of June 22, 2018)

I. Purpose

When work is carried out at a place with a height of 2 m or more, it is a general rule to provide a working floor, and prevent falls in the first place by providing enclosures, handrails, covers, etc., at the ends and openings, etc. of the working floor. However, when such measures are difficult, the employer is obliged to take measures such as having workers use safety belts.

In order to prevent industrial accidents due to falls, the term “safety belts (limited to those for protecting workers from danger due to falls)” was replaced with the term “fall arrest equipment” in item (xxviii) of paragraph (3) or Article 13 of the Order for Enforcement of Industrial Safety and Health Act (Cabinet Order No. 318 of 1972; hereinafter referred to as “the Order for Enforcement”) on June 8, 2018. In addition, on June 19, 2018, necessary revisions were made to add measures to prevent industrial accidents due to falling/tumbling and special education in the Ordinance on Industrial Safety and Health (Ordinance of the Ministry of Labour No. 32 of 1972; hereinafter referred to as “the Safety and Health Ordinance”) and Rules on Special Education for Safety and Health (Public Notice of the Ministry of Labour No. 92 of 1972), and these changes came into force on February 1, 2019.

These Guidelines were established for the purpose of presenting, in an integrated manner, key points from among the items prescribed in the revised Order for Enforcement, items to be carried out by the employer, and items prescribed in the Industrial Safety and Health Act (Act No. 57 of 1972; hereinafter referred to as the “Safety and Health Act”) and related laws and regulations, in order to promote further safety measures through the proper use of fall arrest equipment in combination with the revised Order for Enforcement, etc. In addition to properly implementing the items described in these Guidelines, the employer shall strive to take safety measures that are more suited to the actual situation at the site.

II. Applicable scope

These Guidelines apply to work performed using the fall arrest equipment stipulated in Article 13, paragraph 3, item (xxviii) of the Order for Enforcement.

III. Terminology

1. Parts, etc. constituting fall arrest equipment

(1) Full harness type fall arrest equipment: Fall arrest equipment consisting of parts with a structure for supporting the body load at multiple points such as shoulders, waist, and thighs, when arresting a fall.

(2) Body belt type fall arrest equipment: Fall arrest equipment consisting of a belt-like part worn on the waist of the body.

(3) Lanyard: Equipment consisting of a rope or strap(hereinafter referred to as “lanyard rope, etc.”) for connecting the full harness or body belt to the main rope or other mounting equipment, etc. (i.e., equipment for safely mounting fall arrest equipment, etc.) and a connector, etc. When connecting a shock absorber or winder, this also includes the shock absorber, etc.

(4) Connectors: Equipment for connecting between full harnesses, body belts, lanyards, or mounting equipment, etc.

(5) Hook: A type of connector and one component of a lanyard. A hook-shaped device for connecting a lanyard to mounting equipment or a ring connected to a body belt or full harness.

(6) Carabiner: A type of connector and one component of a lanyard. An annular device for connecting a lanyard to mounting equipment or a ring connected to a body belt or a full harness.

(7) Shock absorber: A device for mitigating the shock produced when arresting a fall. Type 1 shock absorbers have an impact load of 4.0 kilonewtons or less when arresting a fall with a free fall distance of 1.8 meters, and Type 2 shock absorbers have an impact load of 6.0 kilonewtons or less when arresting a fall with a free fall distance of 4.0 meters.

(8) Winder: Equipment for winding up a lanyard strap. Some have a lock function to instantaneously stop unwinding the lanyard when a fall is arrested.

(9) Auxiliary rope: A short rope or strap (hereinafter referred to as “rope, etc.”) which, when a worker moves, is attached to the mounting equipment at the destination before the main lanyard is reattached, in order to keep the worker constantly connected to the mounting equipment

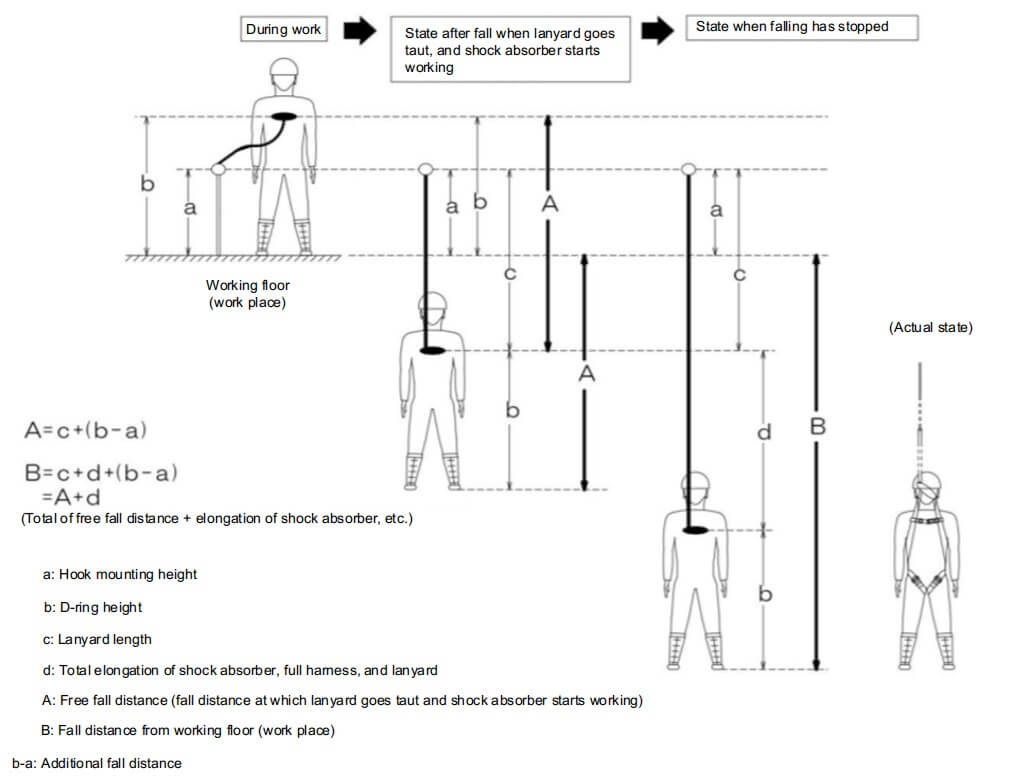

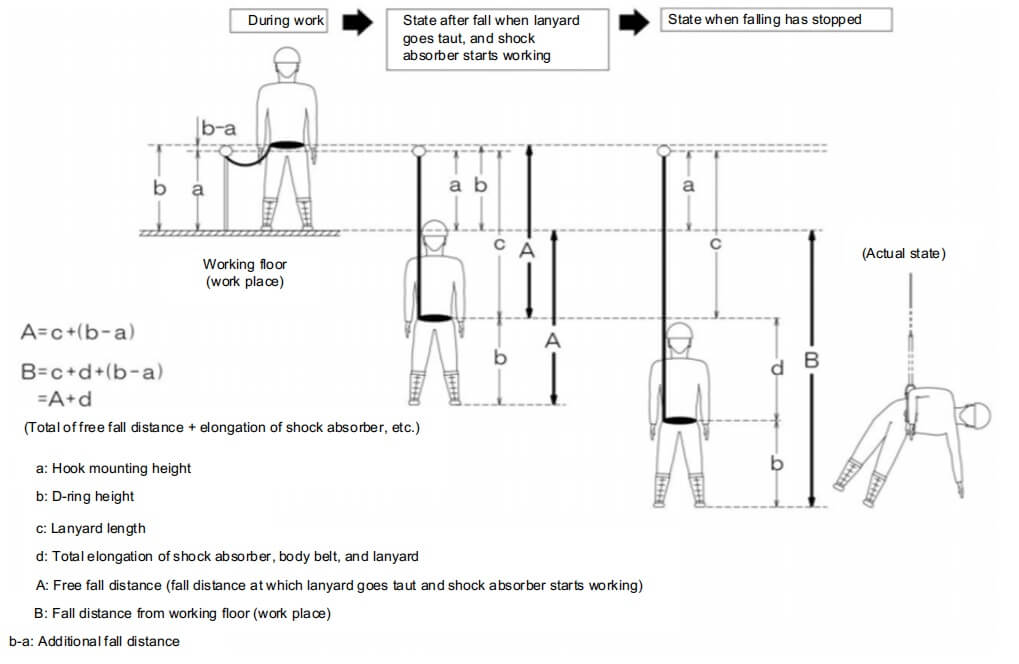

(10) Free fall distance: Distance obtained by adding the length of the lanyard to the distance obtained by subtracting the height of the mounting equipment, etc. for the hook or carabiner (hereinafter referred to as the “hook, etc.”) from the height of the part connecting the lanyard to the full harness or body belt when the worker wears a full harness or body belt (A in Figure 1 and Figure 2).

(11) Fall distance: Distance obtained by adding the free fall distance to the elongation, etc., of the lanyard and full harness or body belt produced when a worker’s fall is arrested (B in Figure 1 and Figure 2).

2. Relating to work via work positioning

(1) Work via work positioning: Work carried out while the body of the worker is held in a U-shaped suspended state by the tension of a rope, etc.

(2) Rope for work positioning: A rope, etc., that is wrapped around the mounting equipment and used to hold the work position of the worker’s body in a U-shaped suspended state by the tension of a rope, etc., adjusted using length adjuster.

(3) Length adjuster: A component part of a rope for work positioning. Equipment for adjusting the length of a rope.

(4) Movement rope: A rope that is fastened to and suspended from a steel tower, used in construction work, etc. on steel towers for power transmission lines.

3. Other related equipment

(1) Vertical main rope: Mounting equipment employing a rope, etc. installed in the vertical direction.

(2) Horizontal main rope: Mounting equipment employing a rope, etc. installed in the horizontal direction.

Figure 1: Fall distance, etc. of full harness type

Figure 2: Fall distance, etc., of body belt type

受講者様のご希望に合わせ、以下のタイプの講習会もご用意しています

このページをシェアする

講習会をお探しですか?