[Chapter 1] Section 2 Scaffolding Material, Structure, and Assembly Drawing④

4 Wedge binding scaffold

The basic members consist of posts with tensioning sections, ledger with tensioning sections, arm timbers with tensioning sections, floor ledger form, brackets with tensioning sections, screw-tube jacking type base fittings, wall ties, and wedge binding scaffold diagonal members or large braces.

- Wedge binding scaffold for building construction

Used for construction work such as building construction with a height of 45 m or less - Wedge binding scaffold for housing construction

Used for construction of low-rise residential buildings such as wooden houses with eaves less than 10m high

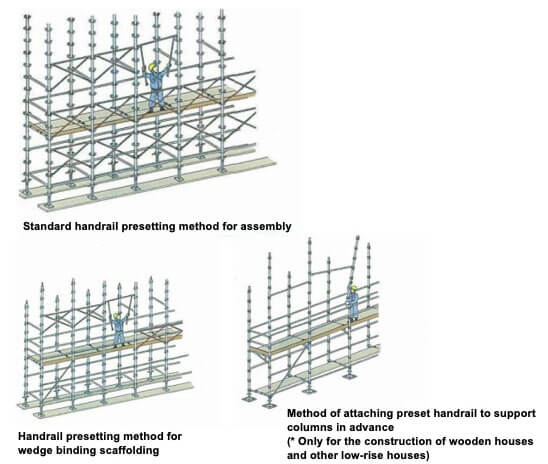

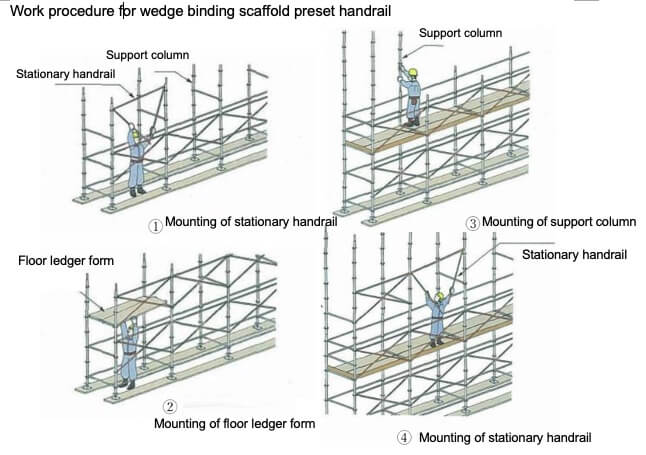

(1) Standard handrail presetting method for assembly

1.As a rule, assembly and dismantling of wedge binding scaffolding for building construction shall be carried out by the handrail presetting method using the preset handrail for wedge binding scaffolding.

2.Wedge binding scaffolding for building construction shall be provided on one or both sides of the wedge binding scaffolding with a preset handrail for wedge binding scaffolding.

3.When using the handrail presetting system for wedge binding scaffolding, be sure to install the handrail and middle rails using ledgers or other materials with tensioning parts before replacing the preset handrail on the top level.

(2)Tensioning method

When assembling wedge binding scaffolding for building construction, securely drive or insert a wedge into the tensioning section of the support column.

When steel pipes for scaffolding are used for members such as large braces, girders, and canes, they should be attached by means of a tensioning bracket and securely tightened.

(3)Apply the following measures to scaffold footings to prevent sinking and sliding.

1.The ground on which the scaffold is to be built should be solid.

2.A shingle or a slab should be used under the screw pipe jacking type base metal fittings, depending on the ground conditions.

3.When using a slab, fix the screw pipe jacking type base metal fittings to the slab with at least two nails, etc. When using a slab, fix the screw pipe jacking type base metal fittings to the slab in accordance with the method used for the slab.

4.Install a bridge batten of foot posts in the girder direction and beam-to-beam direction, respectively. However, if the screw-tube jacking type base metal fittings are fixed to the sill plate with two or more nails, etc., the bridge batten in the girder direction can be omitted.

5.Bridge battens shall be installed as close to the ground as possible, and shall be fastened to the support columns with the respective tensioning sections.

(4) Assemble standards by means of the support columns with tie-downs as follows:

1.The spacing between columns with tie-downs shall be 1.85 m or less in the girder direction and 1.5 m or less in the beam-to-beam direction.

2.The mortises or joints connecting the posts with tie-downs should be secured against pull-outs. The first ledgers on the ground should be installed at 2 m or less.

(5) Install the first ledger above ground not more than 2 m.

(6) Ledger with tensioning section

On the structure where no preset handrails are to be installed, ledger with tie-downs are to be installed every 2 m or less in height.

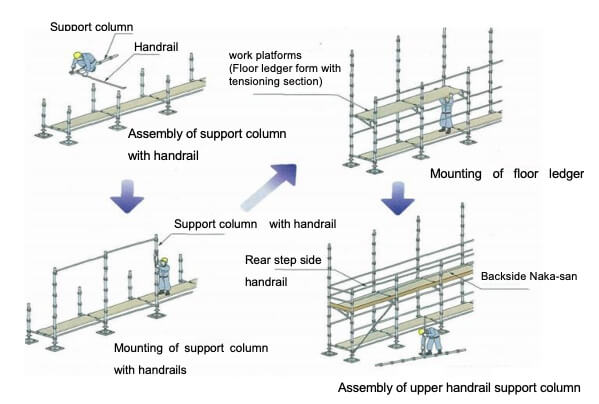

(7) For the installation of the preset handrail for wedge binding scaffolding, use a post with a tensioning section exclusively for the preset handrail for wedge binding scaffolding.

(8) Install arms as follows.

1.Every span of all layers at a height of 2 m or less.

2.When using ledger frames with a floor with a tensioning section, use a bracket with a tensioning section (with a recessed metal fitting) or arm with a tensioning section.

3.When using ledger with floor, use ledger with tensioning section or bracket with tensioning section (fixed type).

4.Brackets with extendable type tensioning sections are not used as arms.

(9)Work floor

Use a ledger frame with a floor or a ledger frame with a floor with a tensioning section for the work floor.

1.Work floor should be at least 40 cm wide.

2.Install the floor over the arm in the beam-to-beam direction.

3.The vertical spacing shall not exceed 2 m.

4.Install continuously and firmly over each span

5.Lay them between the standards (struts with fastening parts) ensuring that there is no space in between.

6.The clearance between work floor is 3 cm or less

7.Securely lock the gripping clamps of the floor ledger form.

8.Securely drive the tensioning part of the floor ledger form and tensioning part into the tensioning part of the arm with tensioning part.

(10)Fall prevention equipment

Install one of the following facilities at the edge of the working floor to prevent falls.

1.Handrails, etc. (generally 90 cm or more in height from the work floor) and middle rails, etc. (35 cm to 50 cm or more in height from the work floor)

2.Preset handrails for wedge binding scaffolding of the handrail installation type.

(11)The equipment to prevent falling objects is as follows.

1.If there is a risk of objects falling from scaffold, install one of the following equipment.

a.Baseboard 10 cm or higher

b.Mesh sheet

2.If installing the mesh sheet, calculate the wind load and reinforce the scaffold is based on the result.

3.Install protective shelves based on the following.

a.Attach protective shelves and supports or lifting members to the arms of the support columns with the tensioner.

b.Install wall ties on the front step side of the scaffold at the location where the shelves and supports or suspension members are attached, for the entire span.

c.Calculate the dead weight and wind load of the shelves and reinforce the scaffold accordingly.

(12)Install one of the following equipment as a brace, etc. on the rear footing side of the scaffold over the entire span of all layers.

1.Install large braces in two intersecting directions every eight layers and eight spans or less, using steel pipes for scaffolding. The inclination shall be approximately 45° to the horizontal, and the steel scaffold pipes shall be attached to each support column with a tensioning part using a tensioning metal fitting.

2.Install wedge binding scaffold diagonals in two directions across every six layers and six spans or less.

3.Install preset handrails for X type wedge binding scaffolding.

(13)Use wall-hanging fittings for wall connection, as shown in the installation.

1.Set vertical intervals of 5.0 m or less and horizontal intervals of 5.5 m or less.

2.Attach wall joint fittings to the building side at a solid point, and attach to the scaffolding near the intersection of the support column with tensioning section and the brace.

(14)If the height is greater than 31 meters:

1.Measure from the highest point of a support column with a tensioning section and use a set of two columns with a tensioning section up for a distance of more than 31 m above the ground.

2.Firmly fix the two sets of the support columns with the tensioning section and steel pipes for scaffolding using the tensioning metal fittings.

3.Attach tensioning fittings to the upper and lower ends of the steel pipes for scaffolding and near the arms of each layer.

(15) Install the stairs as follows.

1.Provide landings at every two or fewer levels.

2.Provide handrails and middle rails at stairs and their openings.

(16)Temporary removal of members

When a part of the scaffold must be temporarily removed for work, confirm in advance that the strength of the scaffold in the removed state will not be significantly reduced, and restore the scaffold to its original condition immediately after the work is completed.

(17)The maximum loading capacity on scaffolding is as follows

1.The maximum loading capacity of scaffolding shall be less than or equal to the values shown in the following table and simultaneous loading shall be limited to two layers.

| Per layer per span | |

|---|---|

| Same layer continuous span loading | 250㎏ |

| Loading other than same layer continuous span | 400㎏ |

2.Notwithstanding the values in the table above, do not load the work floor in excess of the allowable loading capacity of the floor ledger form and the floor ledger form with tensioning section.

3.The total loading capacity of scaffolding above openings consisting of beam frames for wedge-type scaffolding shall be 800 kg or less.

(18)Use the wedge binding scaffold preset handrail in the following ways.

1.When scaffolding are assembled or disassembled, do not remove the preset handrails installed at the topmost level, even when removing loads, etc.

2.If there is a risk of falling on the topmost level where scaffolding are being assembled or disassembled, attach fall prevention equipment to the preset handrails.

3.Use as equipment for mounting fall prevention equipment as follows.

a.Hang the hook of the fall prevention equipment on the preset handrail railing. Only one person is allowed to use the device per frame.

b.Use at least two layers for the vertical distance from the work floor to the ground or machinery and equipment, etc. that may cause a crash.

(19) Indicate the maximum loading capacity on the scaffold clearly where it can be easily seen.

(20)Inspect scaffolding at the appropriate time and in the appropriate manner in accordance with Articles 567 and 655 of the Ordinance on Industrial Safety and Health.

From “Technical standards for the assembly and use of wedge binding scaffolding

地域・講習・人数に合わせてすぐに予約可能

講習会を予約する受講者様のご希望に合わせ、以下のタイプの講習会もご用意しています

このページをシェアする

講習会をお探しですか?