[Chapter 1] Section 2 Scaffolding Material, Structure, and Assembly Drawing⑤

5 Scaffolding for construction of low-rise residential buildings

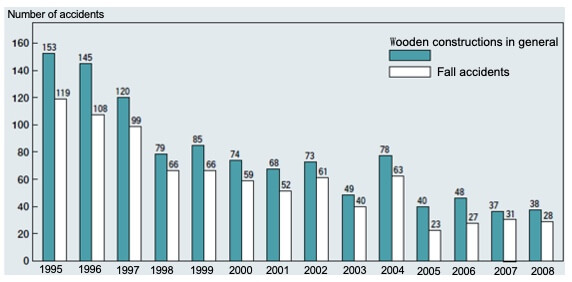

(1)In order to prevent industrial accidents in low-rise residential construction projects, the Ministry of Health, Labor and Welfare (MHLW) established the “Guidelines for Scaffolding Construction Methods” in 1996, which set forth specific procedures and scaffolding installation standards for scaffolding construction methods that precede building work, and has been promoting the use of scaffolding construction methods based on these guidelines. Since then, the number of fatalities due to falls in low-rise residential construction projects has been declining.

However, in February 2006, to further promote measures to prevent accidents in low-rise residential onstruction projects, the guidelines were revised with regard to scaffolding and scaffolding installation methods.

In addition, since the partial revision of the Ordinance on Industrial Safety and Health, which reinforced the prevention of falls from scaffolding, etc., came into effect on June 1, 2009, the provisions of the guidelines that do not meet the standards of the revised Ordinance on Industrial Safety and Health will be raised to the standards stipulated in the revised regulations and administered accordingly.

(2)Major amendments to the Guidelines (revised in February 2006)

1.The scaffolding method has been changed so that when a part of the minimum necessary scaffolding is opened because it is difficult to construct the scaffolding over the entire circumference of the building, the scaffolding for that part shall be constructed promptly and sequentially after the construction work for each floor is completed in order to prevent falls from that part of the scaffolding.

2.To prevent hazards due to unreasonable working posture, it was added that the height of the work floor should be changed as necessary in accordance with the progress of the process.

3.It was added that after bad weather or assembly or partial modification of scaffolding, scaffolding must be inspected for abnormalities, and if abnormalities are found, they must be repaired promptly.

(3) Works to which the Guidelines apply

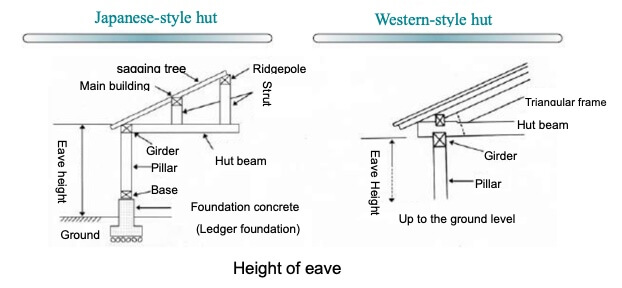

These Guidelines apply to the construction of residential and other buildings with eaves less than 10 m high (excluding buildings of cast-in-place reinforced concrete construction).

Therefore, in addition to the shaft construction method, carry out work according to this Guideline for frame wall construction ( two-by-four construction method), lightweight steel frame construction, lightweight concrete (ALC) construction, and precast concrete construction, when the eaves height is less than 10m.

(4) Scaffolding type

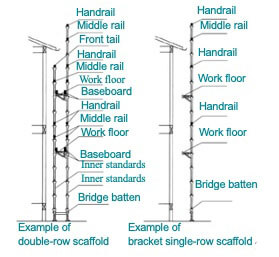

Scaffolding shall be on the double-row scaffolding. However, if the building site is narrow or difficult to install double-row scaffolding, bracket single-row scaffolding may be used.

Scaffolding shall be constructed completely around the entire perimeter. However, if it is difficult to assemble the scaffold completely around the entire perimeter due to the building work, the scaffold may be partially open to the minimum extent necessary.

In this case, the scaffolding on the partially open part must be constructed as soon as possible after completion of the construction work on each floor.

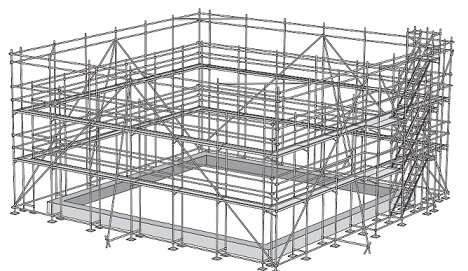

(5) Scaffold presetting is a method in which scaffolding are installed prior to the start of construction work.

1.”Erection work” means work related to the assembly of structural members such as columns, beams, girders, etc., and the attachment of shed beams, shed girders, purlins, ridgepoles, and rafters.

2.”Double-row scaffolding” refers to single-pipe scaffolding with inner standards and outer standards, which are used for construction work on houses, etc.

3.”Bracket single-row scaffold” means single-row scaffolding having a bracket (carrying frame) attached to the standards.

(6) Precautions in work

1.Job-specific construction contractors shall liaise and coordinate with construction workers, etc., and patrol the construction site. In addition, construction firms etc. shall patrol the construction site and inspect the health and safety management status of the construction site, such as the status of scaffolding installation.

2.Work supervisors shall be appointed for the erection of scaffolding 5m or more in height and for the erection of structural members of wooden buildings with eaves 5m or more in height to ensure direct supervision.

・With regard to operations requiring qualifications such as operation of mobile cranes or slinging operations, qualified personnel shall thoroughly implement operations in an appropriate manner.

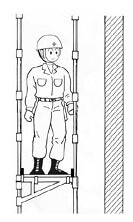

3.Workers engaged in work at high places must wear protective coverings to prevent hazards due to falls.

4.Construction firms, etc. shall endeavor to promote education for new entrants, and job-specific contractors shall provide continuous safety education for workers.

・Construction firms etc. shall ensure that their chief operators etc. actively participate in workshops, training sessions, etc. related to the scaffolding prefabrication methods.

(7)Distance between the outer wall and work floor and fall prevention measures

1.To prevent falls from scaffolding during erection work and before the construction of exterior walls, scaffolding shall be installed so that the exterior wall of the building and the edge of the work floor are as close as possible, and the scaffolding shall be equipped with handrails and middle rails.

If it is difficult to install handrails and middle rails on the front step side, have workers use fall prevention equipment.

2.After exterior wall construction

The distance between the building and the working floor of the scaffolding shall be 30 cm or less. If it is difficult to keep the distance at 30 cm or less, front handrails should be provided on the scaffold.

If it is difficult to provide front handrails, measures shall be taken to prevent falls, such as installing nets or requiring workers to use fall prevention equipment.

(8)When to install

Set up scaffolding after foundation work, backfilling, and leveling are completed, but before erection work begins.

(9)Assembly of scaffold

1.Before assembling scaffolding, check for significant damage, deformation, corrosion, etc., of members and replace them with proper ones if any abnormality is found.

2.Assemble the scaffolding while confirming the work method, work procedures, etc., based on the scaffolding plan, etc.

3.To prevent the scaffold from collapsing, assemble the scaffold while providing a temporary anchorage, etc.

4.Check the location of mobile cranes and the shape of the building in the drawing to ensure that the scaffold is assembled without interfering with the building or obstructing crane work.

(10)Scaffold changes

1.Promptly install scaffolding on the lower roof and over balconies to accommodate changes in the shape of the building as work progresses Change work floor as necessary to ensure that they are at a suitable height for the working posture.

2.When changing a part of the scaffold for the convenience of the work, ensure the safety of workers using the scaffold and be sure to restore the scaffold after the work is completed. If it is difficult to restore the scaffold, promptly contact the contractor constructing the concerned work, the scaffold installer, etc.

(11)Inspection of scaffolding

Before starting the day’s work, inspect handrails, middle rails, baseboards, etc. installed in the area where work is to be performed to ensure that they have not been removed or fallen off, and if any abnormality is found, immediately repair it.

In the event of bad weather such as strong winds, heavy rain, heavy snow, etc., or an earthquake of moderate intensity or greater, or after erection, partial dismantling, or alteration of scaffolding, inspect the scaffolding for any abnormalities as described below, and immediately repair any abnormalities found.

Keep records of these inspections until the work using the scaffolding is completed.

1.Condition of damage, installation and extension of floor material

2.Condition of looseness of standards, connecting and mounting portions of arms,ledgers, brackets, etc.

3.Condition of damage and corrosion of tensioning materials and clamps

4.Removal and coming off of handrails and middle rails

5.Condition of mounting and removal of baseboards, etc.

6.Condition of settling and sliding of footings

7.Whether or not reinforcement materials such as braces, sills, and wall joints are installed or removed.

8.Damage to standards, ledgers, and brackets

Outline of the main structural elements of scaffolding according to the guidelines on scaffold presetting method

| Classification | Mounting position and dimensions |

|---|---|

| Fall prevention from roof | If the roof slope is 6/10 or more, or if the roof is made of slippery material, install work floor at intervals of not more than 2 m with a width of at least 20 cm. |

| Fall prevention from eaves | 1.Protrude the standards of the scaffold above the eaves of the roof, and install handrails on the standards. The handrail shall be at least 85 cm above the eaves of the roof, and shall be at least 35 cm high and no more than 50 cm above the eaves of the roof. 2.The distance between the eaves and the standards should be less than 30 cm. In addition to 1. and 2. , many companies are using non-slip materials at the height of the eaves to prevent falls from the eaves. |

| Sheet, etc. | 1.In principle, sheets, etc. shall not be installed in the preset scaffolding construction method until the scaffolding is reinforced with wall ties, etc. after erection work is completed. If it is necessary to install the sheets before the erection work, they should be installed after sufficient reinforcement to prevent the scaffold from collapsing due to wind loads, etc. 2.After the erection work ・In order to prevent accidents caused by scattering and falling materials, tools, etc. from roofs and work floor of scaffold, etc., it is desirable to install sheets, etc. ・Sufficiently reinforce scaffolding to take account of the sheet’s own weight and wind load. ・Use dimensions corresponding to the intervals of the scaffolding standards and ledgers. ・Tightly fasten all doves to the scaffold to prevent easy detachment. |

| Mounting position of handrail, etc. |

(1)Handrail height must be at least 85 cm. (2)The middle rail height must be 35 cm or more and 50 cm or less. |

| Baseboard | As measures to prevent objects from falling, baseboards or mesh sheets with a height of 10 cm or more should be installed. |

| Ledger spacing | The distance between the ledgers must not exceed 2 m. |

| Best ledger in world |

The first ledger on the ground shall be placed not more than 2 m. However, scaffold with two standards and scaffold of a structure where adjacent surfaces are bound were installed at a location not exceeding 2.3 m. |

| Wall tie or stay | 1. Install a brace on each side of the building before erection. However, if the standard is narrow and it is difficult to set up the stay, tighten the entire perimeter of the scaffold. 2. For scaffolding other than those with stays built on each side after the erection work, the entire perimeter of the scaffolding must be completely assembled, each side shall be mutually tightened, and wall ties shall be promptly installed on each side. 3. If it is difficult to install wall ties due to the structure of the building or other reasons, provide firestops and compressors, etc. If one side of the scaffold is long, provide a headstock to reinforce the scaffold. |

| Brace | Place a diagonal bracelet with an inclination of approximately 45 degrees on each surface over all layers and spans. |

| Root girdle | 1.Place bridge batten as low as possible. 2.If there is an opening for removing the bridge batten, reinforce it with diagonal bracings, etc. |

| Work floor | The width of work floor is more than 40 cm. However, if it is difficult to provide work floor with a width of 40 cm or more for bracket single-row scaffolding, work floor with a width of 24 cm or more may be provided. |

| Boards and paving boards, etc. |

Use baseboards for scaffolding However, if there is no risk of unequal subsidence of the ground, shingle may be used. If unequal subsidence is observed, adjustment should be made by means of jack-type base fittings, etc. |

| Elevating equipment | Install stairs on the scaffold. The treads should be evenly spaced, at least 20 cm wide, with a raised height of no more than 30 cm, and handrails should be installed. |

Changes in the incidence of fatalities in house building construction work due to falls

地域・講習・人数に合わせてすぐに予約可能

講習会を予約する受講者様のご希望に合わせ、以下のタイプの講習会もご用意しています

このページをシェアする

講習会をお探しですか?