[Chapter 1] Section 1 ②

1. Types, structures, and handling methods for typical equipment②

2. Mounting equipment, etc. for fall arrest equipment

Unlike other protective equipment such as helmets and masks, fall arrest equipment cannot be effective by itself. It is necessary to connect it to equipment, etc. that can withstand the impact of falling.

The following are examples of typical mounting equipment and materials used in various types of work.

■ Vertical main rope

(b) Mounting equipment employing rope, etc. installed in a vertical direction. (Used when moving up and down, etc.)

■ Grip for vertical main rope

When moving up and down using a vertical main rope, this grip is attached to the main rope, and used by connecting with fall arrest equipment.

The grip slides easily upward, but when force is applied downward, it locks to prevent falling.

To reduce the fall distance in case of an accident (i.e., to lessen the shock), the worker moves up and down while keeping the grip and main rope linkage point at a position as high as possible.

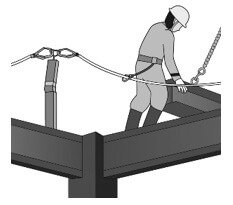

■ Horizontal main rope and main rope tensioner

These terms refer to mounting equipment using ropes, etc., for attaching the hook of fall arrest equipment. This equipment is used when moving horizontally during work such as assembly of steel frames or scaffolding, or work on the roof of low-rise housing.

The main rope tensioner pulls and holds the rope with a force of about 0.2-0.3 kN so there is no looseness.

Generally, the structure is such that rope is pinched and held when a force is applied in the tension direction.

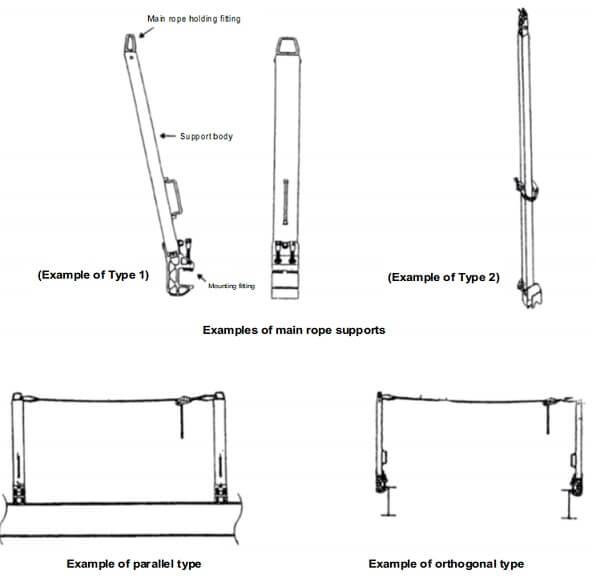

■ Main rope supports

These are supports for installing a horizontal main rope (used in work such as assembly of steel frames).

When installing a main rope support, read the instruction manual carefully and pay attention to the correct setting direction and mounting method. Do not use if bent or corroded, etc.

Support types

| Type 1 | This type is for constructing main rope support systems mainly used in steel frame assembly work, etc. It is mounted to the flange, etc. of a steel beam using the metal fitting of the support, tensioned by a tensioner using the main rope for support, and used as mounting equipment for safety belt fall arrest equipment. There are orthogonal, parallel, and combined types in terms of the relation between the direction of the H-shaped steel and the direction of the main rope for support. |

| Type 2 | This type is for constructing main rope support systems mainly used in assembly and dismantling of prefabricated scaffolding, etc. It is set up by using the leg posts, horizontal members, and other parts of the frames which constitute the prefabricated scaffolding, stretching a main rope for the support, providing bracing rope, and using as mounting equipment for safety belt fall arrest equipment. |

(From “Certification Standards for Main Rope Supports, Main Ropes for Supports, and Tensioners,” Scaffolding and Construction Equipment Association of Japan)

|

For the main rope, use wire rope 9 to 10 mm in diameter or synthetic fiber rope 16 mm or more in diameter. Inspect for damage before use (e.g., 7 or more broken rope yarns). Set up at the necessary points in advance, and replace it as necessary. Also, when stretching rope, provide tension so that there is no slack. One main rope should be used by only one person and never by more than one worker at the same time. |

|

(See: Guidelines for the Prior Handrail Construction Method, and Appended Table 4: How to Use Main Rope Equipment)

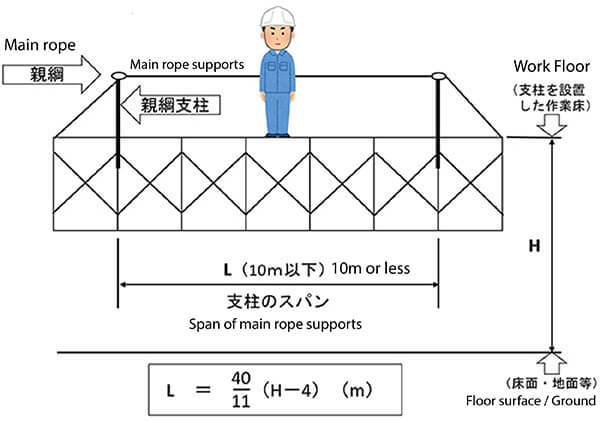

- The span of main rope supports (meaning the interval between main rope supports holding the main rope; same applies below) shall be 10 m or less.

- The span (L) of main rope supports that can be used shall not exceed the value calculated by the following formula.

- The value is based on the vertical distance (H) between the working floor on which the main rope support is installed and the floor surface, etc. where there is a danger of collision.

- Tighten the main rope to the main rope supports with a tensioner, etc. so the rope does not sag.

- When the full harness type is used, the horizontal main rope is stretched so it is positioned above the D-ring on the worker’s back.

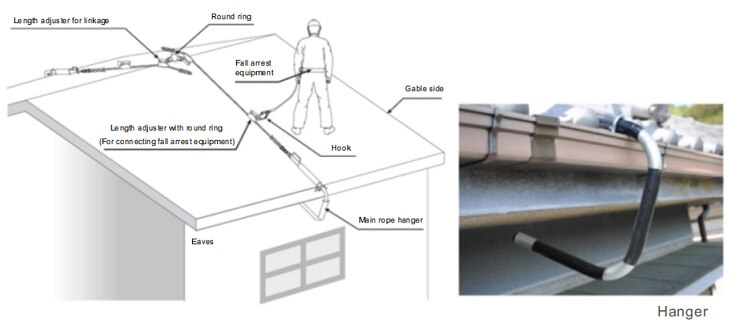

■ Main rope for roof work

|

This system is used by linking with a horizontal main rope, etc. during roof repair work and other work on sloping surfaces. There are also various other systems, such as a system in which an auxiliary main rope is connected to the main rope (in the eaves direction) and fall arrest equipment is used via an attached length adjuster. |

|

■ Main rope hanger and length adjuster for linkage

In this system, a hanger is attached to the eaves and the main rope is stretched by operating a length adjuster for linkage at the ridge of the roof.

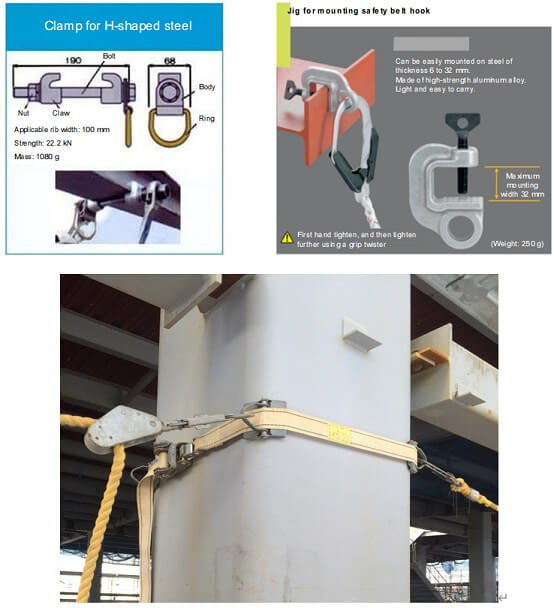

■ Other special-purpose mounting fittings, etc.

There are metal fittings such as clamps, loop-shaped belts, and other equipment attached to steel columns, beams, and other members, to serve as hangers for fall arrest equipment.

■ Safety block

A safety block is type of fall prevention equipment for work at high places, and it is often used by installing it at a construction site such as a building, and connecting the hook at the end to the D-ring of the worker’s safety belt.

The length of the wire rope varies and should be selected to suit the work site where the block will be used.

When it is pulled out at high speed, the block has a stop function like the seat belt of an automobile, and a type with a built-in shock absorber is also commercially available.

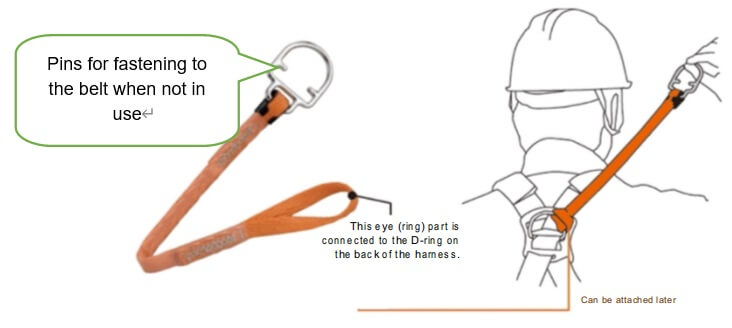

※Auxiliary Belt (handy strap)

Since it is difficult to connect a hook to a D-ring on the back by oneself, auxiliary belts have been devised, sold and used.

受講者様のご希望に合わせ、以下のタイプの講習会もご用意しています

このページをシェアする

講習会をお探しですか?