[Chapter 1] Section 1 ③

2. Methods of inspection and maintenance of equipment used for work

1. Mounting equipment for fall arrest equipment, and inspection and maintenance

|

Even if a worker has fall arrest equipment, it will be useless if it is not used at a place where there is a risk of falling. Also, if it is used, it is meaningless if the equipment it is mounted to is imperfect, or there is no place to mount it to in the first place. Therefore, before use, be sure to check whether any mounting equipment exists, whether it has any problems, and so on. |

|

[Reference: Fall accidents while using a safety belt (From 2010 to 2014)]

Total 170 (Only reports from workplaces in the construction industry were extracted based on the Report on Worker Death, Injury and Illness.)

(1) Cases of collision with a beam, etc. while dangling or falling 17

① Collision at locations other than the ground, etc. 15

② Prolonged compression by the safety belt 1

③ Impact load on body via the safety belt 1

(2) Cases where a person wearing a safety belt collided with the ground, etc. 16

① Wide installation spacing between main rope supports 1

② Insufficient tension on main rope 2

③ Long lanyard 3

④ Low working floor

(for main rope, less than 4m; for other, less than 2m) 10

(3) Cases where the hook came off, etc. resulting in collision with the ground, etc. 137

① Main rope broke or came off 10

② Lanyard broke 5

③ Handrail, etc. where hook was attached came off due to improper fastening, etc. 25

④ Hook attached at an unsuitable place came off 64

⑤ Safety belt came off 10

⑥ The entire scaffolding, etc., where the hook was attached collapsed. 20

⑦ Unknown 3

(Source: Data from the Third Review Meeting on Proper Regulation of Personal Protective Equipment for Fall Prevention)

※Regardless of whether there is an accident, it is illegal to have workers work at a high place (i.e., work at a height of 2 m or more where there is a risk of falling/tumbling) without any mounting equipment for fall arrest equipment, or with mounting equipment that is defective or inadequate.

Even if a worker voluntarily carries out dangerous work on his/her own initiative, saying “it’s okay,” this does not lessen at all the responsibility of the employer (company) “to ensure that workers work under safe conditions.”

In addition, there are many cases in which a supervisor (i.e., foreman) entrusted by the employer (company) to direct and supervise work at the site, is also held responsible.

[Examples of the concept of responsibility for mounting equipment under the Industrial Safety and Health Act]

- Not having installation equipment in the first place is the responsibility of the employer (company, representative).

Example) Although it was a work site where a main rope should be provided, the company did not have such equipment, so the workers were made to work without a place to attach a hook.

- If mounting equipment is available, but workers are made to work without installing it, it is the responsibility of the site supervisor.

Example) Main rope equipment was loaded in the construction vehicle, but the work was only expected to take a short time, so installation was judged to be unnecessary, and workers were made to work without installing it.

- If mounting equipment is available, but defective, it is the responsibility of the employer or site supervisor.

Example) Workers were made to use a main rope which was deteriorated and damaged due to neglect of inspection. When the worker tumbled, the main rope broke and the worker collided into the ground.

(The company is likely responsible for inadequacies of the inspection system and guidance/education, encouraging the use of defective equipment, and so forth; and the site supervisor and person in charge of inspection are likely responsible, from a practical standpoint, for neglecting inspection, etc.)

Note)

The above is a rough guideline for judgment, and among actual examples sent to a prosecutor for violation of the Industrial Safety and Health Act, there are various cases depending on the individual situation.

The Industrial Safety and Health Act was drafted with emphasis mainly on the responsibility of employers, but when an accident actually occurs, it is the workers themselves who face dire consequences, so it is natural for them to carefully check the equipment they rely on for protection, and strive to work safely even without instructions from supervisors.

2. Inspection items for mounting equipment, etc. and examples of disposal criteria (See the table below)

To ensure safe use, be sure to inspect before starting work.

If inspection shows that equipment meets the disposal criteria, do not use it. Replace it with new equipment.

| Part name | Inspection item | Disposal criteria |

|---|---|---|

| Main rope, subrope | Damage | 7 or more rope yarns broken

|

| Wear | Conspicuous wear | |

| Deformation | Deformation (twisted hump). | |

| Looseness or coming apart of Satsuma knit | Satsuma-knit that is loose or coming apart

|

|

| Deposition of chemicals or paints | Deposition of chemicals or adhesion and hardening of paint

|

|

| Deformation, etc. of thimble | Thimble deformed or missing

|

|

| Tensioner | Quality of lengthening/shortening function | ・Difficulty lengthening/shortening ・Damaged or missing spring ・Poor function |

| Spring breakage | Broken or missing, and incapable of holding | |

| Claw wear | Reduction by 1/2 or more in bumps on claw edge | |

| Rust | Overall rust | |

| Deformation | Deformation visible to the eye | |

| Damage | Gouging of 1 mm or more in depth, or fine fissures | |

| Rivet wear or rattle | ・Worn rivet heads or crimped parts (worn by about 1/2) ・Rattling rivets |

|

| Hook fitting | Abnormal function | ・Failure of safety device or latch to operate reliably ・Damaged or missing spring |

| Deformation | Deformation visible to the eye | |

| Damage | ・Gouging of 1 mm or more in depth ・Fine fissures |

|

| Rust | Overall rust | |

| (Carabiner)corrosion | White rust (corrosion) | |

| Rivet wear or rattle | ・Worn rivet heads or crimped parts (worn by about 1/2) ・Rattling rivets |

|

| Safety block | Quality of lock function | Strap that does not wind or unwind smoothly |

| Quality of strap winding/unwinding | Strap that does not wind or unwind smoothly | |

| Splitting or deformation of body | Splitting of length 3 mm or more in the body or deformation visible to the eye | |

| Deposition of chemicals or paint on strap | Core material exposed due to damage, burning, abrasion, etc. | |

| Deposition of chemicals or paint on strap | Twisting, or deformation and waviness over entire length

|

|

| Breaking of sewing | Sewing thread broken at one or more places | |

| Length adjuster | Quality of lengthening/shortening function | Difficulty lengthening/shortening |

| Damaged or missing spring | Poor function | |

| Spring breakage | Broken or missing, and incapable of holding | |

| Claw wear | Reduction by 1/2 or more in bumps on claw edge | |

| Length adjuster Carabiner Ring |

Rust | Overall rust |

| Deformation | Deformation visible to the eye | |

| Damage | Gouging of 1 mm or more in depth, or fine fissures | |

| Rivet wear or rattle | ・Worn rivet heads or crimped parts (worn by about 1/2) ・Rattling rivets |

|

| Slide (Grip for vertical main rope) |

Quality of mounting to vertical main rope | Cannot be mounted to vertical main rope due to spring damage, etc. |

| Deformation, damage | ・Defective operation (safety device or lock device do not completely close) ・Deformation visible to the eye |

|

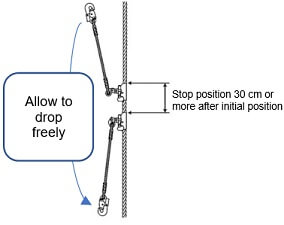

| Confirmation of stop function | ・When the hook is lifted, and the slide is allowed to drop freely, the distance to stopping is 30 cm or more ・Fails to stop when hook is pulled downward

・Fails to stop when hook is pulled downward |

(Excerpt from Standard Work Manual for Installation of Safety Equipment to Prevent Falls)

3. Other mounting equipment (main rope supports, H-steel clamps, etc.) shall not be used if any of the following apply:

・Has been subjected to a fall impact

・Has conspicuous deformation or damage such as corrosion

・Has damage or deposits on fastening bolts

・Has damage to ropes, belts, or straps (See the table above)

・Has visible deterioration or damage other than the above that clearly affects function

受講者様のご希望に合わせ、以下のタイプの講習会もご用意しています

このページをシェアする

講習会をお探しですか?